inSIGHTS

- Layers of the

facade

The perfect façade for thermal and acoustic comfort

Our mixed Steel and Concrete system

The starting point of the system we use is a detailed study of the building tradition, in order to transform it into a system that allows the construction of a complete house inside a factory and that, when transferred to the plot, only requires minor finishing work. Constructive simplicity is sought so that the building as a whole complies comfortably with all the requirements of the different regulations.

The steel framework provides the required flexibility and speed, but concrete is not to be dispensed with because of its structural, acoustic and thermal properties, so a solution is sought that unifies both materials.

For the floor slabs, the best system to avoid vibrations that could be uncomfortable for the users of the building is found in the collaborating plates. For the façades and roofs, a material rarely used in the construction sector is sought, which is a very high-performance concrete that stiffens the structure and improves airborne acoustic insulation.

Finally, a continuous envelope was chosen for the façades and roofs, which provides extraordinary hygrothermal properties.

1. Layered façade configuration

Our façades are composed of five layers, optimised to guarantee maximum thermal and acoustic insulation:

- Exterior finish coat: (porcelain, wood, monolayer, natural stone…): this layer, in addition to providing an aesthetic finish, acts as a first barrier against the elements, protecting the home from the wind, rain and sun.

- External insulation: we place a layer of thermal insulation that protects against the entry of cold in winter and heat in summer, optimising energy efficiency.

- High density concrete: the heart of our façade are high-density precast concrete slabs, which provide strength and structural resistance. Their high density and thermal inertia contribute to improve thermal and acoustic insulation.

- Interior insulation: a second layer of insulation between the concrete and the interior of the house ensures that the indoor temperature remains stable and minimises energy losses.

- Interior finishing layer: finally, the interior cladding is incorporated, a layer of plasterboard that leaves enough space between it and the interior insulation to incorporate the necessary installations behind the wall.

Our facades are composed of five layers, optimised to guarantee maximum thermal and acoustic insulation:

- Exterior finish coat: (porcelain, wood, monolayer, natural stone…): this layer, in addition to providing an aesthetic finish, acts as a first barrier against the elements, protecting the home from the wind, rain and sun.

- External insulation: we place a layer of thermal insulation that protects against the entry of cold in winter and heat in summer, optimising energy efficiency.

- High density concrete: the heart of our façade are high-density precast concrete slabs, which provide strength and structural resistance. Their high density and thermal inertia contribute to improve acoustic and thermal insulation.

- Interior insulation: a second layer of insulation between the concrete and the interior of the house ensures that the interior temperature remains stable and minimises energy losses.

- Interior finish coat: finally, the interior cladding is incorporated, a layer of plasterboard that leaves enough space between it and the interior insulation to incorporate the necessary facilities behind the wall.

2. Thermal benefits of the façade

The combination of these layers allows our houses to achieve a very low thermal transmittance (U-value close to 0.2 W/m²K)*, ensuring that the house maintains a constant temperature throughout the year. This translates into:

- Lower energy consumption: inHAUS houses are designed to maintain stable temperatures, reducing the need for heating in winter and air conditioning in summer.

- Economic savings: By reducing energy consumption, owners can save up to 30% on their annual energy bills, compared to other types of buildings that do not have these levels of insulation.

* Compared to traditional brick facades, which can have thermal transmittance values of around 1.5 W/m²K, our modular system with concrete and insulation significantly reduces heat losses. In addition, traditional facades do not always achieve the same level of thermal performance without significantly increasing wall thickness.

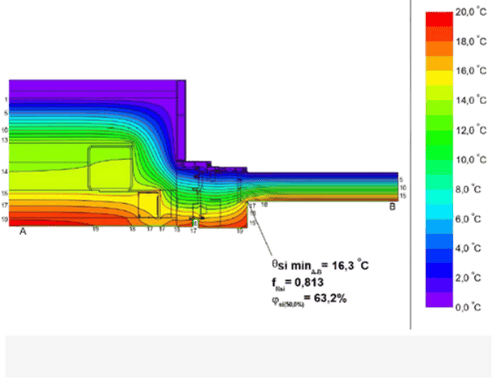

To obtain appropriate façade values, it is essential to install a window profile with the best thermal and acoustic characteristics, and the required glass for its orientation and layout (low emissivity, solar control, etc.); it is also necessary to bring the façade insulation to the carpentry.

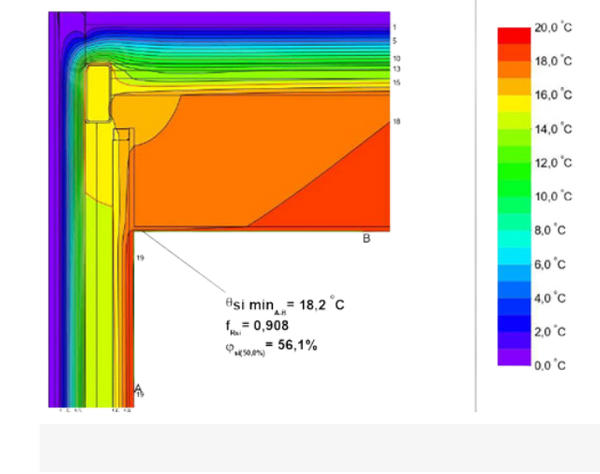

We show below the thermal data of an inHAUS façade, where it can be seen that the execution of our façade system provides low transmittance values, even in the weakest points such as the meeting of the façade with the roof or the window jamb.

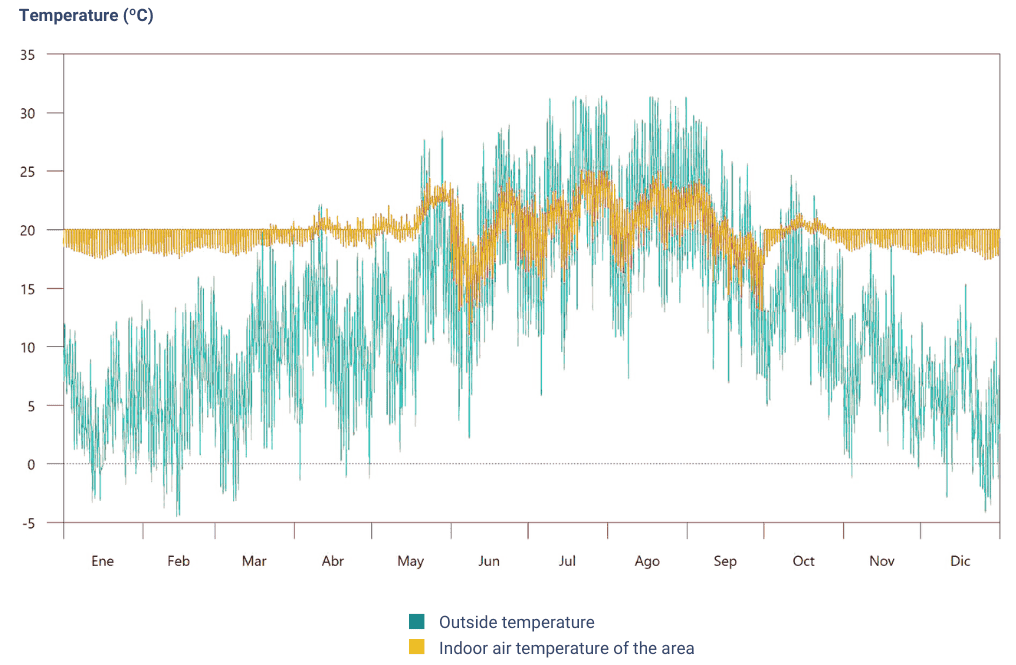

The Hygrothermal Comfort of the building is analysed with a calculation programme and with real data from a finished house.

It can be seen that the indoor temperature remains very close to temperatures of 18-23°C.

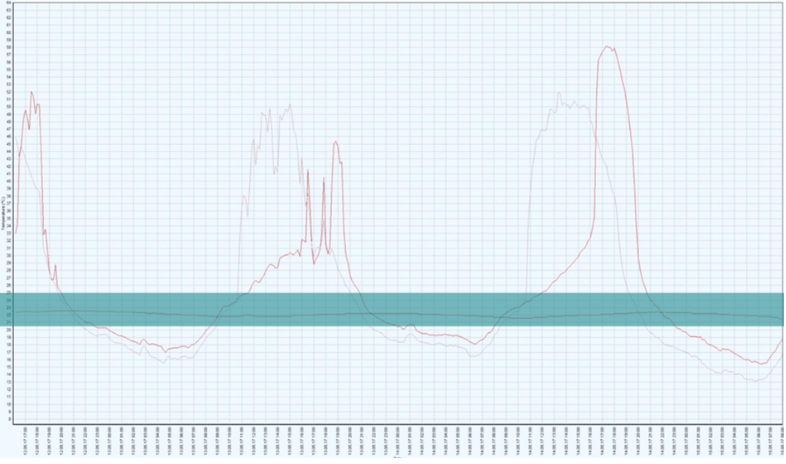

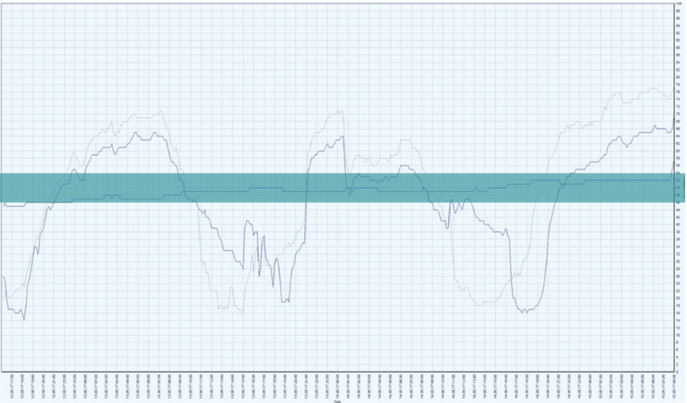

The following tables show the actual data from the analysis with the Klimalogg system, which collects the temperature from two outdoor and one indoor sensor, and the humidity data from two outdoor and one indoor sensor. Note: corresponds to the analysis of the building for 72 hours, without human presence:

TºC

The outer sensors (South and West) show a minimum of 17°C and a maximum of 58°C. The indoor sensor is practically a horizontal line of 22°C.

Humidity

The outdoor relative humidity varies from 14% to 76%. Indoors (without people, but also without the ventilation and heat recovery system activated), the relative humidity only rises from 46 to 54%.

3. Acoustic benefits of the façade

The density of the precast concrete and the double insulation inside and outside contribute to the excellent sound insulation of our houses. The noise reduction we achieve with our system is more than 45 dB, which guarantees a quiet environment, even in busy urban areas.

The opaque part of the facades comfortably meet the requirements of the regulations and it is the door and window openings that are the weak points of the study. At inHAUS, we installed floor-to-ceiling windows in all rooms, most of which are more than three metres wide.

As in the thermal study, the choice of good carpentry and glass is fundamental to homogenise the whole of the envelope.

Between interior enclosures, the overall acoustic reduction index RA ≥ 33dBA is also met.

In the case of impact noise, we place the acoustic attenuation bands in those cases where the standard requires it or where the client requests it (e.g. we have built a music room with an acoustic battery inside a house, near the living room and bedrooms, and also cinemas with the necessary soundproofing elements in walls, floors and ceilings).

Facade layers

Maximum insulation with 5 facade layers

Thermal benefits

Lower energy consumption – greater economic savings

Traditional building 1.5 W/m²K

inHAUS system 0.2 W/m²K

Acoustic benefits

The density of the precast concrete and the double insulation guarantee a quiet environment.

Conclusion

The façade of our homes is designed to offer exceptional thermal and acoustic performance, which translates into greater comfort for residents. The combination of materials such as high-density concrete, together with an efficient insulation system, makes it possible to maintain constant interior temperatures throughout the year, significantly reducing energy consumption. In addition, the acoustic insulation system ensures quiet environments without disturbing noise, even in urban environments with high noise pollution.

Facade layers

Maximum insulation with 5 facade layers

Thermal benefits

Lower energy consumption – greater economic savings

Traditional building 1.5 W/m²K

inHAUS system 0.2 W/m²K

Acoustic benefits

The density of the precast concrete and the double insulation guarantee a quiet environment.

Contact us

Whether you are an individual or a professional, do not hesitate to contact us for further information, to request a personalised quote or to make any enquiry.

Contact form

Consult models and prices

In our Catalogue 111 you have more than a hundred models of houses to choose from. Register to access information and prices of all models.